This is a Club Layout Being built by a Team of Club members

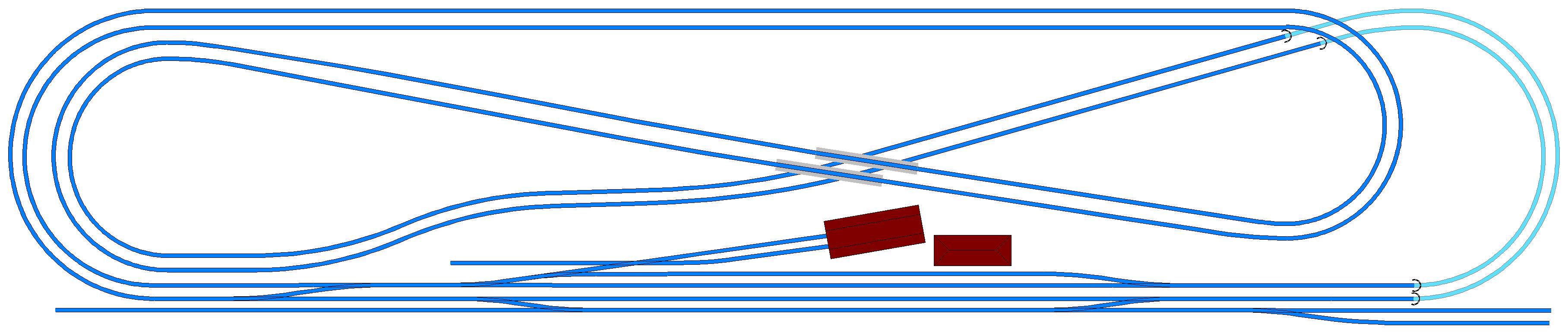

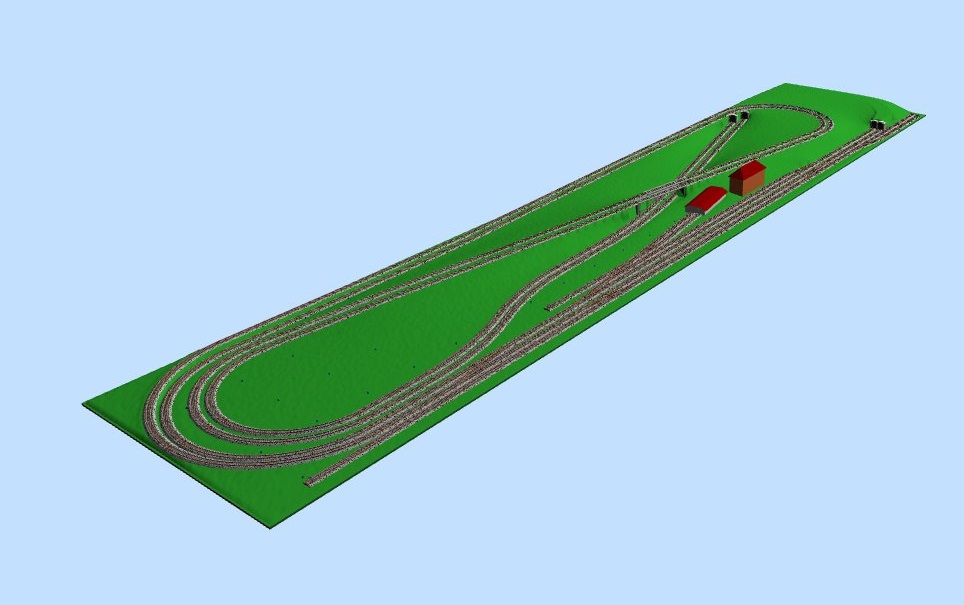

An ‘N’ gauge layout, it features a folded-8 track plan with a four-road through station and a small loco depot. It is designed to create the “Railway in the Landscape” and allows for continuous running of long trains. The train control is via DCC and points etc operated by small R/C servos using MERG EzyBus modules.

December 2023

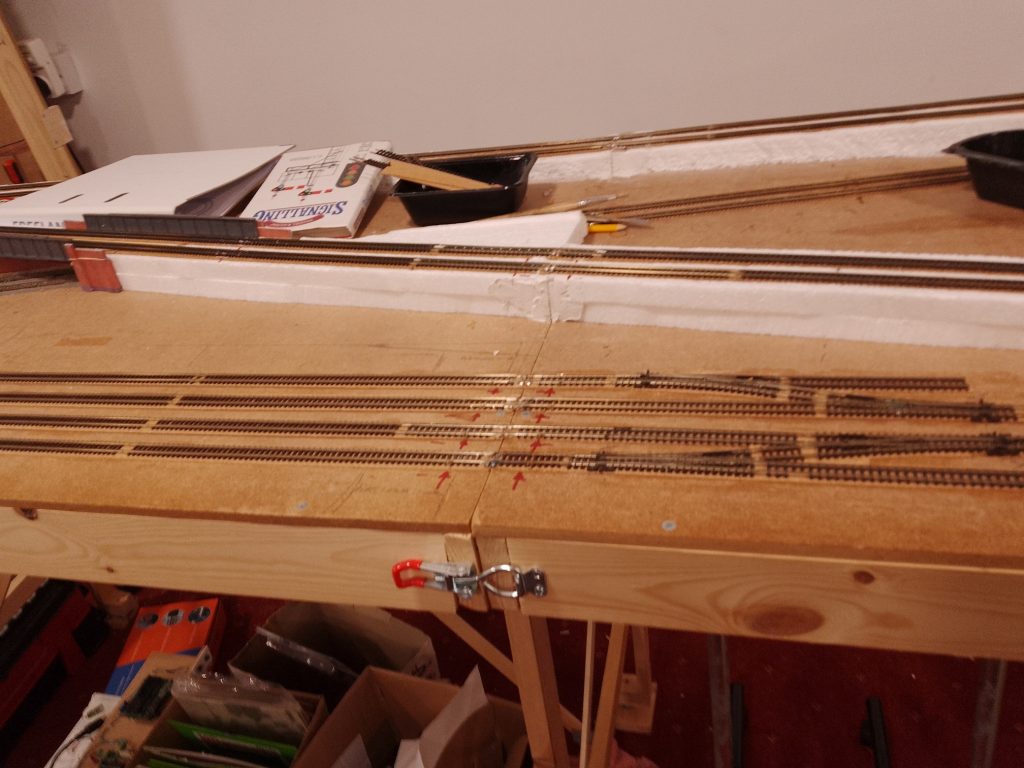

All track is laid and wiring commences with the DCC bus cables, 24/0.2 stranded.

Progress Report – April 2024

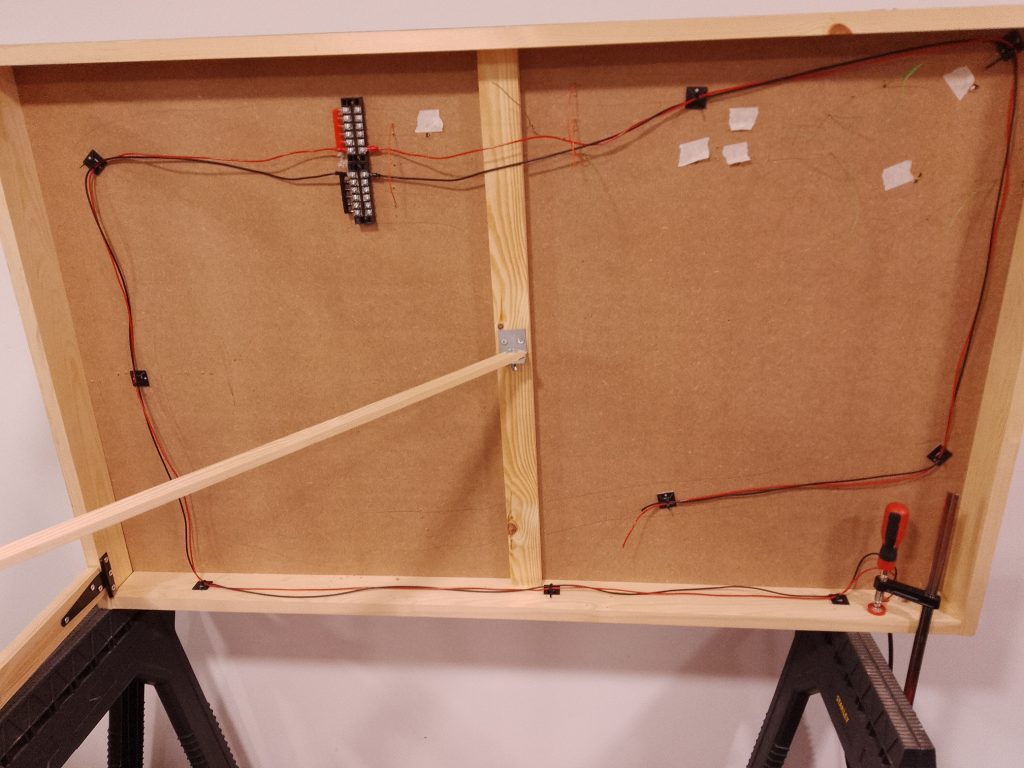

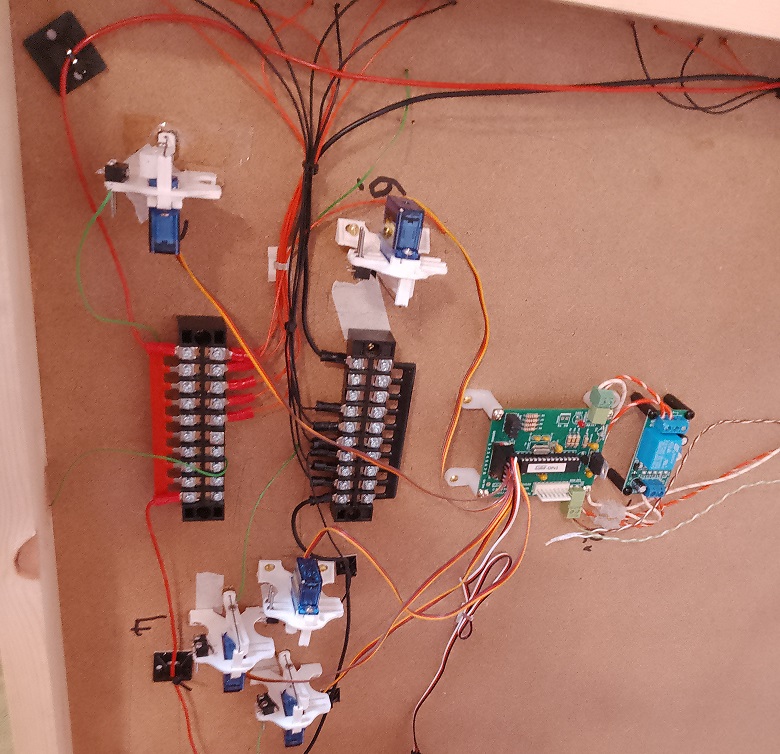

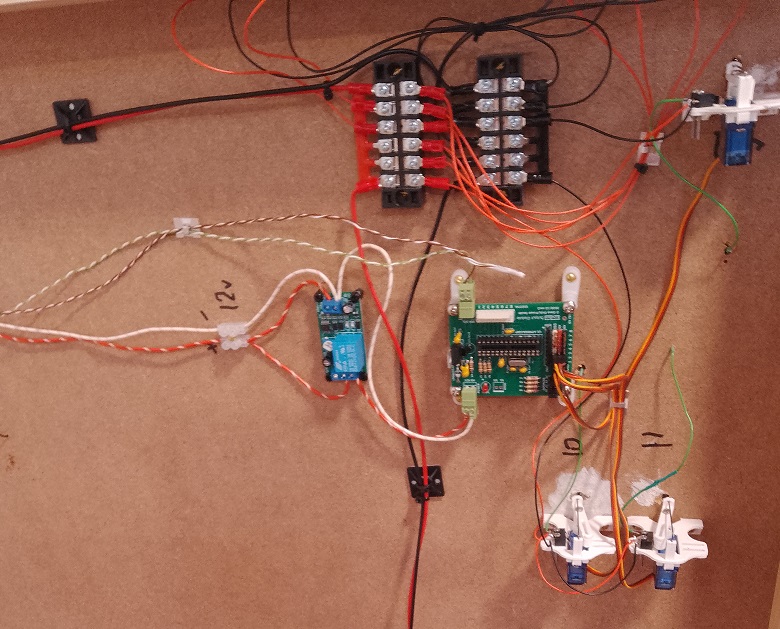

All track power and servo wiring is now complete, although DCC only needs two wires (the 24/.02 red & black in the pictures) connecting it to the track requires droppers on each individual section of track and the points frog polarity connections to the servo micro switches – a lot more wires! Then the I2C bus for the EzyBus modules and the 12vdc supply add more wires. That’s all done and tested, and the servo movements are programmed. Now we are starting track testing with DC rolling stock which has already highlighted a couple of issues, nothing untoward so far.

Work is underway on a few buildings, the station platform, station office building, the engine shed and signal box and we are adding lighting to these – more wiring!

We should have the track ballasted and be showing running trains under DCC by Hoveton.

The pictures below show the MERG output modules, the 12vdc and I2C bus wiring and the 12vdc delay start relays

May 2024

The layout debuted at the Hoveton Show on May 26th and although we had a few teething problems performed well throughout the day. We didn’t get to ballasting the track, it was rusty rail painted and we ran two to three trains under DCC as planned. Watch this space for the next developments and its next outing in August.

Jul 2024

Layout is fully tested and working, ballasting is almost complete and work is well under way on the scenery. The station, engines shed and signal boxes have been built as have several other buildings for the village scene. We will be ready to show at Stalham in August in a much more advanced state than at Hoveton

October 2024

Since the outing at Stalham, we realised that the poor running we experienced was down to poorly constructed baseboards and warping of the MDF top caused by excessive wetting during ballasting. Consequently we decided to start over and build new and stronger baseboards. The old ones were carefully stripped of track, wiring components and accessories; the track cleaned of ballast and wiring – we have probably saved about 80% of the track and all the electronics.

Tony Everett obtained the new timber at a very good price and built the new baseboards at home. I joined them together albeit with a minor alignment error, the legs have been fitted and we have begun re-planning the track. We decided that trying to run multiple coach trains around radius 1 curves wasn’t working so we have decided to use radius 2 and 3 only and this has meant a redesign of one end placing the ‘inner’ tracks above the outer ones using an open viaduct. It has also meant replacing our radius 1 curves and the medium points. Replacements have been found at good prices on eBay and Amazon and track laying has started. We hope to be able to exhibit at Hoveton in 2025.

January 2025

Track laying is well advanced, Tony has constructed the various gradients and slopes and we should be in good position to begin wiring very soon. However, it is unlikely that we will make sufficient progress so that the layout will not appear to have progressed at all to the exhibition audience so we are proposing to withdraw Eight Acres from Hoveton 2025 and plan on Stalham for August. We can, if it will help with workshop space, work on wiring on board at a time until say after Herrington is shown at Norwich on April 12th when we will want to fully erect the layout again for track testing.

April 2025

The layout has been dismantled to make way for Herrington to be fully erected but work continues in the workshop with Tony & I adding the wiring. This is a mix of the salvaged I2C bus and new wires for the DCC bus. It’s slow and a bit tedious and is taking up a lot of space in the workshop. However one board is now complete and the second is well on the way; we should finish the third one during May. Next job is to power it all up, check for electrical continuity and program the controller with the servo movements. As we do that we can add the frog polarity connections and then we’ll be ready to re-erect the whole layout and begin track testing.

Clive Morris has donated some scenery items and the Club has purchased his entire stock of locos, coaches etc so we have enough to be able to run a few trains. As this is all Great Western it suits my tastes perfectly but I can imagine there are some who might think differently.

I don’t anticipate being exhibition ready this year but we might be able to be a work-in-progress by Stalham if required.

July 2025

Track laying is complete and wiring is also complete. Slow progress mainly due to a couple of errors in marking out cable runs properly plus the difficulty in working on one board at a time in the workshop.

Now that the layout is fully assembled we have started track testing using DC, then when that is completed we will convert to DCC and test with full length trains. I expect this will take a few weeks and then we will be able to move on to track painting and ballasting. Tony has already constructed the “Village” scene and the removable baseboard section and work is continuing on the other scenic items offline.

Following a discussion one evening in the Club Room, we have decided to remove the Loco depot and coaling stage and replace this part of the layout with a small goods shed & sidings. This is more in keeping with the layouts concept of a double track, mainline through station, no locos would be shedded in such an environment but a pick-up goods train might well be expected.

October 2025

Track testing has shown up quite a few problems with gauge narrowing on the curves, and some distortion caused by soldering and excessive ballast. In particular our 4-6-0 locos are proving reluctant to negotiate radius 2 set track curves despite the manufacturer’s claim that they will negotiate down to radius 1. The issue is mainly the front bogie derailing around these curves, John Larkins has helped greatly in identifying the track issues and has also added extra weight to the front bogies. One loco has an issue with the connecting wires to the tender so I purchased replacements and a spare set. We have also removed the ballast from the two areas that were done as a test. This did improve things slightly but as we continued to experience problems we decided to replace the suspect set track curves with new ones. The first set replaced showed a big improvement and that area now is problem free. However, the upper level track is also showing the same symptoms so that is being replaced as well. During the removal of the track it was realised that the baseboard was too thin and flexible so that is being remedied at the same time.

The revised plan for the goods yard has been adopted, track is laid and wiring to the DCC bus has been done. Clive has also built the goods shed and modified the main platform to incorporate a bay. This all adds three points to the centre board for a total of 7 which is the maximum for the electronics without adding more modules – the benefit of using a bus-based system for control. It needed additions to the control panel of two switches and a couple of LEDs but no more wiring is required, just set the control program for the new points.

All this has resulted in additional expense that was not planned for or anticipated and now we are down to our last £30. We know this won’t last so reluctantly we must ask for additional funding to assist with the future. As this is likely to consist of mainly low cost scenic materials, buildings etc., we feel an additional £250 is not unreasonable. Hopefully, when this is done we can get on with painting the track, retesting and then ballasting. Should keep us busy up to Christmas! Looking ahead, we are not likely to be ready for Stalham but Hoveton 2026 should certainly be possible

January 2026

The track testing continued and showed up more gauge narrowing and distorted set track on the inner curves on left hand board so reluctantly we had to relay that entire section. The new track tested OK but then we had to add the DCC bus dropper wires which took up a few sessions. Then an elusive track short appeared, a momentary short when one of the crossovers was moved. It turned out to be caused by a combination of faulty connections to the bus and adjustment to the frog polarity switch. . I’m still working on these as a new one just appeared, meanwhile track painting is proceeding well with some work still needed on the goods yard. Next up is ballasting and we have ordered some from Eezyloads as there was none suitable or in sufficient quantity in stock. We will be holding a team discussion very soon to finalise the plans for the scenery and then we can start to make it look like a model railway.

EXHIBITION REQUIREMENTS

| Layout Size | 12′ x 2’6″ |

| Operating space | 16′ x 6′ |

| Number of operators | Two |

| Number of cars to transport | Two |

| Maximum distance for travel | 90 minutes from Stalham |

| Tables & chairs required | 2 chairs |